In the capsule filling industry, maintaining operational efficiency and cost-effectiveness is of utmost importance. Index recognizes this and provides an indispensable service by rejuvenating aged or worn-out capsule fillers. Our specialized rebuilding service breathes new life into your machines, ensuring they meet the stringent standards of modern production lines. By revitalizing equipment, Index helps you sustain peak productivity without the investment required for brand new machinery.

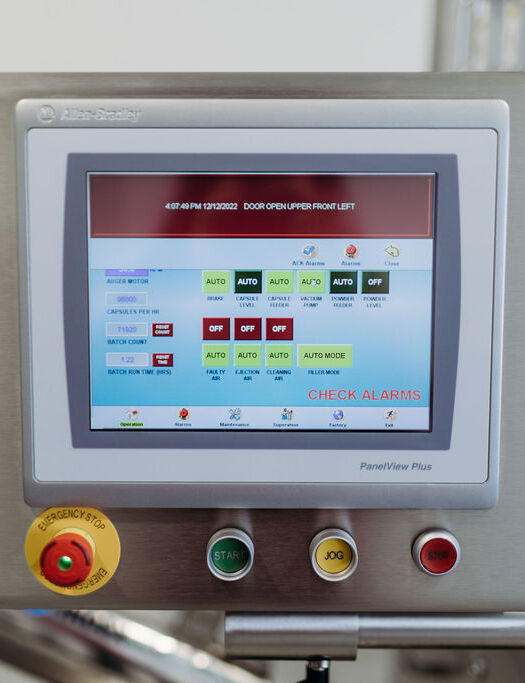

The remanufacturing process for capsule fillers involves a comprehensive series of steps to ensure each machine is restored to optimal performance. This includes rebuilding critical drives, replacing essential components like bearings, seals, and gears, and refurbishing major structural elements. Additionally, a new control system is installed to modernize the machinery, complemented by a new set of tooling to ensure precision in capsule filling. Each remanufactured unit comes with a one-year warranty, demonstrating the company’s commitment to quality and customer satisfaction.

Contact Index today to learn more about our expert training services.

Capsule Filler Spare Parts

Avoid production downtime with Index's spare parts, engineered with precision for capsule filling machines.

Training

Field Service

Leverage Index's expert field service for on-site support and optimization to maximize your capsule filling efficiency.

Control Systems Upgrades

Modernize your control systems with comprehensive upgrade services designed to improve efficiency and reliability.